Press Release

Next step in the transformation: Central plants ordered for Power4Steel – Europe’s largest decarbonization project

11 October 2024

The SHS – Stahl-Holding-Saar Group (SHS Group) with its shareholdings Dillinger, Saarstahl and ROGESA has awarded the decisive contracts for the direct reduction plant (DRI) and the two electric arc furnaces (EAF). Following the funding commitments from the federal and state governments for Europe’s largest decarbonization project, the order for the central components is a major milestone on the way to a “green” future for Saarland’s steel industry.

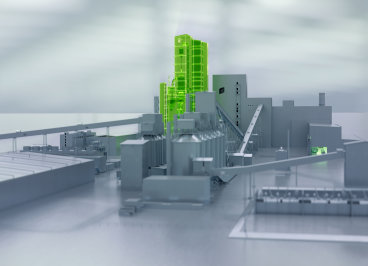

The direct reduction plant will supply reduced iron pellets to the two production sites in Dillingen/Saar and Völklingen. The plant at the Dillingen site has an annual production capacity of around two million tons of direct reduced iron and is based on innovative Midrex Flex technology, which offers the flexibility to work with various mixing ratios of natural gas and hydrogen. Plant construction firms Primetals Technologies, Midrex Technologies Inc. and the DSD Steel Group have been commissioned to build the plant.

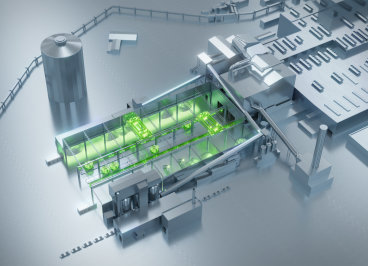

In addition to the DRI plant, the contracts for the electric arc furnaces (EAF) for Dillingen and Saarstahl have also been awarded. These plants will produce CO2-reduced steel from the iron pellets produced in the DRI plant with the addition of steel scrap. The EAF for heavy plate manufacturer Dillinger is also being built by Primetals Technologies and the DSD Steel Group. SMS Group was chosen to build the EAF for wire rod and bar manufacturer Saarstahl.

The DRI plant and two electric arc furnaces are the core components of the decarbonization project of Saarstahl, Dillinger and ROGESA, with a production capacity of 3.5 million tons of crude steel per year. The SHS Group is thus converting 70 percent of its total capacity to CO2-reduced production in just one step.

With the use steel scrap and initial quantities of hydrogen, the systems enable carbon emissions to be cut by up to 55 percent by the early 1930s. This corresponds to an annual reduction of 4.8 million tons of CO2. This means that these Saarland-based steel manufacturers are the only companies capable in the first step of achieving the EU’s “Fit for 55” climate target by 2030, if the corresponding infrastructure and economic efficiency are in place.

Because of the complexity of the system configuration and the additional infrastructure, the SHS Group has carried out extensive preliminary planning for Power4Steel. As a result, an exceptionally advanced level of detail was achieved in the planning phase of the project in order to prepare for the smoothest possible construction phase. Commissioning is planned for 2028/29.

The total investment for the conversion to “green” steel production, including environmental design, infrastructure and logistics measures, amounts to around EUR 4.6 billion. The companies are receiving EUR 2.6 billion in federal and state funding for this pioneering project, with the remaining funding being provided by the companies themselves.

With the awarding of these contracts, Dillinger, Saarstahl and ROGESA are systematically pursuing the goal of climate-responsible production in Saarland. At the same time, they are laying the foundations for a future hydrogen economy in the Greater Region and thereby securing the future of the industrial location.

Quotes

Stefan Rauber, Chairman of the Board of Management of Aktien-Gesellschaft der Dillinger Hüttenwerke and Saarstahl AG

“Today marks a decisive milestone for our decarbonization project. We are very glad to have strong partners at our side. We are making history in order to create the future. We will offer our customers at Dillinger and Saarstahl a high-quality portfolio of carbon-reduced steel and overall become a pioneer of decarbonization in Europe. To accomplish this, however, we need the unwavering backing and support of policymakers. We are firmly committed to climate protection as well as to Germany and Saarland as a business location. For this reason, we expect an active industrial policy at all levels, which supports energy-intensive companies in Germany and creates internationally competitive conditions. Because industries that must produce significantly more expensively in Europe and in Germany must not suffer because they remain loyal to the location; companies that invest in Germany must also be supported by Germany.”

Markus Lauer, Chief Finance and Procurement Officer at Aktien-Gesellschaft der Dillinger Hüttenwerke and Saarstahl AG

“Following the funding commitment of EUR 2.6 billion from the federal and state governments less than a year ago, Power4Steel is taking concrete shape with the order for the core components. We are thus implementing the funding as planned and investing considerable sums ourselves in climate protection and in securing our competitiveness. We see this project as ensuring a successful future for our company, our employees, the region, the environment and future generations. And for our customers as well, of course, who can now rely on highly innovative, climate-friendly steel products in the tried-and-tested quality from Saarland.”

Dr. Peter Maagh, Chief Technology Officer at Aktien-Gesellschaft der Dillinger Hüttenwerke and Saarstahl AG

“With today's award, we are launching an unparalleled production conversion: 70 percent of our capacities are now being transformed into CO2-reduced steel production. The partnership with Primetals Technologies, DSD, Midrex and SMS is an important building block on our path to climate-friendly steel production in Germany. We are confident that we will be able to implement Power4Steel on schedule with these experienced and reliable partners.

Andreas Viehböck, Head of Upstream Technologies at Primetals Technologies

“The transition to green steel production will not happen overnight; we will see a step-by-step process towards carbon neutrality. With this investment, Dillinger and ROGESA are set to reach their mid- to long-term goals in terms of decarbonization. The solutions from Primetals Technologies and Midrex will allow them to gradually ramp up the use of hydrogen, while adapting to a changing energy landscape. We are very happy to support them in this endeavor and beyond.”

Claude M. Pirson, DSD Steel Group, DSD Steel Group Supervisory Board

“DSD is delighted to be part of the ‘green steel’ transformation projects of the SHS Group at the Dillingen site. The fact that we, as a company from Saarland, are now able to help in the transition from traditional blast furnace steel production to CO2-reduced steel production – and thus also to make Saarland fit for the future as a location for industry – fills us with pride.”

Jochen Burg, CEO SMS Group

“We are proud to play a key role in Europe's green steel transformation with this major project for Saarstahl, which belongs to the SHS – Stahl-Holding-Saar Group (SHS Group). The project highlights the long-standing partnership between SHS and SMS group. With an installed power rating of 300 MVA, the new EAF is the biggest ever built by the SMS Group and will set a new milestone in the carbon-neutral future of the steel industry in Europe.”

K. C. Woody, President and CEO of Midrex Technologies Inc

“The decision for MIDREX Flex technology enables Dillinger and ROGESA to transition to hydrogen-based steel production at the pace that matches the availability of sufficient gas supply, while significantly reducing their current carbon emissions. DRI-based steelmaking provides a pathway to a sustainable future, both economically and environmentally, and our technology solutions offer the flexibility and performance to turn the promise into success.”

The project is supported by:

- Federal Ministy for Economic Affairs and Climate Action on the basis of a decision by the German Bundestag

- Ministry of Economics, Innovation, Digitalisation and Energy Saarland

About SHS – Stahl-Holding-Saar GmbH & Co. KGaA

SHS – Stahl-Holding-Saar GmbH & Co. KGaA is an operational management holding company with around 13,000 employees. As Germany’s third largest steel producer, its companies produce around 5 million tons of steel that is ready for shipment. It actively performs tasks for the two major steel companies in Saarland, Aktien-Gesellschaft der Dillinger Hüttenwerke (Dillinger) and Saarstahl AG. In December 2023, the EU Commission approved the funding of the common decarbonisation project Power4Steel by Dillinger, Saarstahl and the joint subsidiary ROGESA Roheisengesellschaft Saar mbH in the amount of 2.6 billion euros by the federal and state governments. For more information: www.stahl-holding-saar.de

Martin Reinicke